Our Company

Annual Output: 2,000 Tons of Plastic Extrusion Profiles, Exported World Wide.

Dachang Plastic & Hardware Processing Factory is a leading enterprise specializing in Plastic Extrusion profiles, leveraging advanced technology and over 20 years of experience to deliver customized, high-quality solutions globally. With manufacturing centers in Guangzhou, Shanghai, and Beijing, our nationwide network ensures rapid response and efficient delivery, with products exported worldwide, earning market trust.

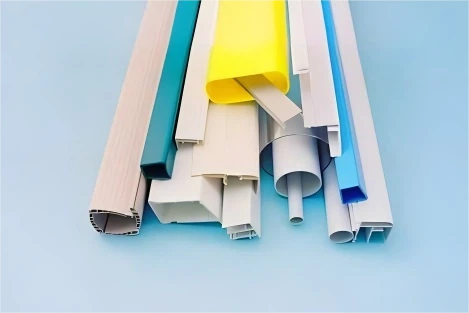

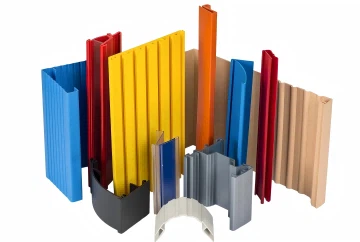

Using engineering plastics like PVC, PP, PC, ABS, and TPU, our precise Plastic Extrusion process creates tailored profiles for construction, automotive, electronics, medical, and packaging industries. Unlike general suppliers, we focus on custom solutions, supporting high-volume production for large-scale projects, ensuring quality and reliability.

What We're Offering

-

Manufacturing Capability

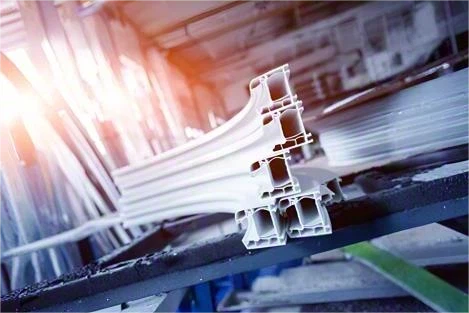

Our advanced workshop with 40+ machines ensures rapid development of plastic extrusion profiles, delivering precise, scalable solutions for small and large orders efficiently.

-

Environment-Friendly

Our plastic extrusion profiles meet RoHS and REACH standards, ensuring eco-friendly, safe solutions for global markets, maintaining sustainability and high performance.

-

Customized Service

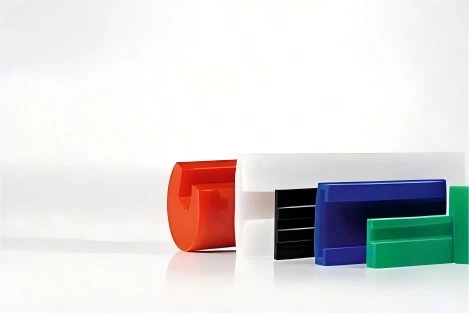

With extensive expertise, we provide tailored plastic extrusion profiles, offering design consultation and material selection for precise, industry-specific solutions with optimal performance.

-

Product Quality

ISO 9001-guided production ensures plastic extrusion profiles meet rigorous standards for accuracy and durability through strict quality control, delivering reliable products consistently.

Provide customized services

-

Product Structure DesignOur Plastic Extrusion design service creates tailored profiles with complex cross-sections, optimized for architectural, automotive, or industrial applications, ensuring precision and performance.

-

Material Selection and OptimizationWe optimize Plastic Extrusion profiles using PVC, PP, PC, and more, ensuring durability, compliance, and performance for medical, electronics, and construction industries.

-

Mold Development and ManufacturingOur advanced Plastic Extrusion mold workshop rapidly creates custom molds for unique profiles, supporting efficient production for furniture, pipes, and precision components.

-

Large-Scale Production SupportWith 40+ machines, our Plastic Extrusion process delivers 2,000 tons annually, ensuring high-volume, consistent profiles for construction, automotive, and packaging industries.

Material properties

-

Material VersatilityOur plastic extrusion profiles products leverage a wide range of high-performance engineering plastics, including PVC, PP, PE, PC, ABS, HIPS, TPU, TPE etc, tailored through advanced Plastic Extrusion processes to meet diverse application needs.This versatility allows us to produce profiles with varying properties such as flexibility, rigidity, transparency, or chemical resistance, ensuring compatibility with industries like construction, automotive, electronics, and medical.read more

Material VersatilityOur plastic extrusion profiles products leverage a wide range of high-performance engineering plastics, including PVC, PP, PE, PC, ABS, HIPS, TPU, TPE etc, tailored through advanced Plastic Extrusion processes to meet diverse application needs.This versatility allows us to produce profiles with varying properties such as flexibility, rigidity, transparency, or chemical resistance, ensuring compatibility with industries like construction, automotive, electronics, and medical.read more -

Cost-EffectivenessOur plastic extrusion profiles offer competitive pricing through efficient manufacturing, minimizing waste and ensuring durability for construction, packaging, and industrial applications.High-volume plastic extrusion profiles production ensures economies of scale, maintaining quality and reliability for large-scale projects with cost-effective, high-performance solutions.read more

Cost-EffectivenessOur plastic extrusion profiles offer competitive pricing through efficient manufacturing, minimizing waste and ensuring durability for construction, packaging, and industrial applications.High-volume plastic extrusion profiles production ensures economies of scale, maintaining quality and reliability for large-scale projects with cost-effective, high-performance solutions.read more -

Fire ResistanceOur Plastic Extrusion profiles, particularly those made from materials like PVC and PC, are engineered to meet stringent fire safety standards, such as UL94-V0 ratings, ensuring enhanced safety in critical applications.Our plastic extrusion profiles incorporate flame-retardant additives, ensuring ignition resistance and safety for construction, electrical enclosures, and infrastructure, meeting stringent fire safety standards.read more

Fire ResistanceOur Plastic Extrusion profiles, particularly those made from materials like PVC and PC, are engineered to meet stringent fire safety standards, such as UL94-V0 ratings, ensuring enhanced safety in critical applications.Our plastic extrusion profiles incorporate flame-retardant additives, ensuring ignition resistance and safety for construction, electrical enclosures, and infrastructure, meeting stringent fire safety standards.read more -

Precision ExtrusionOur state-of-the-art plastic extrusion profiles ensures exceptional precision in the production of profiles with complex cross-sections, tight tolerances, and consistent quality.Utilizing advanced machinery and rigorous quality control under the ISO 9001 system, our Plastic Extrusion technology delivers profiles with smooth surfaces, accurate dimensions (up to 500mm in width), and reliable mechanical properties.read more

Precision ExtrusionOur state-of-the-art plastic extrusion profiles ensures exceptional precision in the production of profiles with complex cross-sections, tight tolerances, and consistent quality.Utilizing advanced machinery and rigorous quality control under the ISO 9001 system, our Plastic Extrusion technology delivers profiles with smooth surfaces, accurate dimensions (up to 500mm in width), and reliable mechanical properties.read more

Customized profile picture examples

-

Read MoreClear PVC Price Tag

Dachang's plastic extrusion profiles in clear PVC enhance retail shelving displays with visibility, durability, and easy installation, offering custom sizes and colors.

Dachang's plastic extrusion profiles in clear PVC enhance retail shelving displays with visibility, durability, and easy installation, offering custom sizes and colors. -

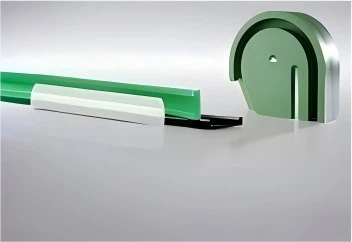

Read More46mm Impact PC Covers

Our 46mm plastic extrusion profiles in PC provide strength, heat resistance, and light diffusion for LED systems, customizable for industrial and outdoor lighting.

Our 46mm plastic extrusion profiles in PC provide strength, heat resistance, and light diffusion for LED systems, customizable for industrial and outdoor lighting. -

Read More60° Extruded Acrylic Lens

Dachang's acrylic extrusion profiles provide precise light control, transparency, and durability for LED and architectural lighting, supporting OEM/ODM customization.

Dachang's acrylic extrusion profiles provide precise light control, transparency, and durability for LED and architectural lighting, supporting OEM/ODM customization. -

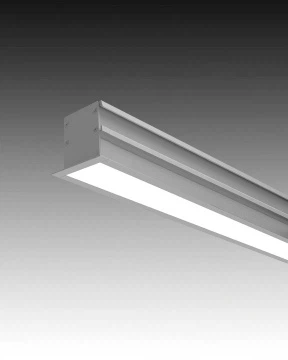

Read More71/46mm Zigzag Linear Cover

Our zigzag plastic extrusion profiles in PC/PMMA offer modern aesthetics, glare reduction, and light diffusion for office and LED systems, fully customizable.

Our zigzag plastic extrusion profiles in PC/PMMA offer modern aesthetics, glare reduction, and light diffusion for office and LED systems, fully customizable.

The areas of plastic extrusion profiles

-

01Construction and Architecture

-

02Automotive Industry

-

03Electronics and Electrical

-

04Medical and Healthcare

-

05Packaging Industry

-

06Industrial Manufacturing

Why choose us

Dachang Plastic Hardware Processing Factory, with over 20 years of expertise, is a reliable leader in Plastic Extrusion, delivering tailored solutions globally. Our 16,000-square-meter facility, equipped with 45 large-scale and 20 small-scale production machines, supports the creation of diverse Plastic Extrusion profiles for industries like construction, automotive, and electronics. This robust infrastructure ensures high precision and scalability for custom projects.

Our Plastic Extrusion expertise enables us to produce profiles using materials like PVC, PP, PC, and ABS, meeting stringent RoHS and REACH standards. Certified by ISO 9001, we guarantee consistent quality and durability in every Plastic Extrusion product, from LED light covers to medical tubing. Our client-centric approach and advanced Plastic Extrusion technology allow us to deliver cost-effective, high-performance solutions that meet exact specifications.

COOPERATION PROCESS